Ceiling Systems and Cleanroom Wall Systems

- Curtains, Strip Entrance Doors, Bi-folding Curtains, AirBlock™ Softwall System, New Mounting System

- Furniture, Chairs/Seating, Storage Cabinets, Tables

- Custom Stainless Steel Products, Benches, Carts, Custom Sink for Cleaning Glass Carboys, Cleanroom Cabinet, Sterile Glove Dispenser

- Ceiling Systems, T-Grid Systems, Ceiling Panels, Light Fixtures

- Cleanroom Wall Systems, Frame Systems

- Laminar Flow Equipment, Wall/Ceiling Modules, Pass Thru Cabinets

Specialty Production Equipment

View the following specialty production equipment:

Q/PECS | Custom Stainless Steel Products

Ceiling Systems

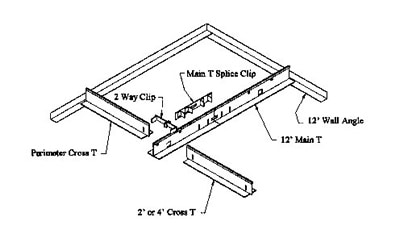

T-Grid Systems & Gel Systems

We Offer 2″ and 1-1/2″ T-Grid Systems

- The Cleanrooms International 2″ Structural T-Grid System is designed to meet the exacting standards of the cleanroom industry. Applications include food services, food processing, pharmaceutical, electronic, medical devices, chemical, and hospital industries.

- Suspension hardware provides easy adjustment for installing the ceiling dead level.

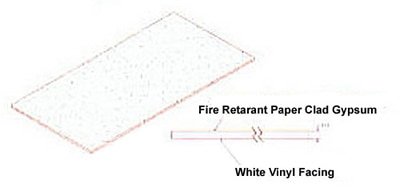

CRI Ceiling Panels

- CRI ceiling blanks are used in spaces not occupied by SAM Fan/Filter Modules, Ceiling Filter Modules, or light fixtures.

- Class 1000 – 100,000

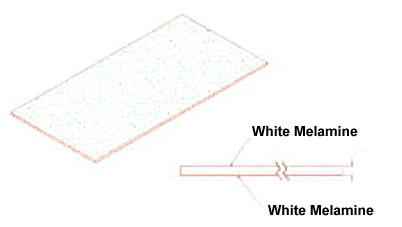

Cleanguard Ceiling Panels

- Clearguard Ceiling Panels are designed for low particle emission and maximum cleanability in cleanrooms and other environmentally controlled areas.

- Class 100</li>

Light Fixtures

Strip Light

- The CRI Teardrop light fixture is designed for use in vertical, laminar air flow cleanrooms.

- A narrow airflow design minimizes turbulence.

Lay-In Light Fixture

- Sealed flushed door frame and sealed housing.

- The housing and door are designed to fit a standard 2′ x 4′ ceiling grid opening.

- Sealed housing and door frames allow relamping without contamination of the clean areas.

Cleanroom Wall Systems That Meet Your Needs

Where critical environmental conditions must be maintained, modular cleanroom wall systems and prefabricated kit wall systems offer you a cost-effective alternative to conventional construction… without compromising quality, durability, or cleanroom efficiency.

We understand your needs, so we combined the latest, most effective cleanroom technology with a modular design that can be installed, modified, expanded, and relocated quickly and easily to meet your changing needs.

Our cleanroom wall systems provide an ultra-clean environment, with effective control of airflow, pressure, temperature, humidity, and filtration. We also give you the flexibility of a variety of core materials, exterior panels, and finishes to meet your requirements for acoustic and thermal insulation, chemical resistance, and static control.

Hardwall Modular Cleanrooms

Hardwall Modular Cleanrooms are designed with each individual customer’s needs in mind to provide ideal systems ranging from ISO Class 1 to 9. Our Cleanrooms have been installed in a broad range of industries and countries. The modularity of the wall system allows for easy expansions and modifications after the installation of the original design.

Since 1971 Filtration Technology Inc. continues to demonstrate proven leadership as FILTRATION and Contamination Control Specialists by providing the highest quality in Cleanroom Facilities and Air & Liquid Filtration to all types of commercial, industrial, and specialized manufacturing facilities.