Ceiling Systems and Cleanroom Wall Systems

- Curtains, Strip Entrance Doors, Bi-folding Curtains, AirBlock™ Softwall System, New Mounting System

- Furniture, Chairs/Seating, Storage Cabinets, Tables

- Custom Stainless Steel Products, Benches, Carts, Custom Sink for Cleaning Glass Carboys, Cleanroom Cabinet, Sterile Glove Dispenser

- Ceiling Systems, T-Grid Systems, Ceiling Panels, Light Fixtures

- Cleanroom Wall Systems, Frame Systems

- Laminar Flow Equipment, Wall/Ceiling Modules, Pass Thru Cabinets

Specialty Production Equipment

View the following specialty production equipment:

Q/PECS | Custom Stainless Steel Products

Ceiling Systems

T-Grid Systems & Gel Systems

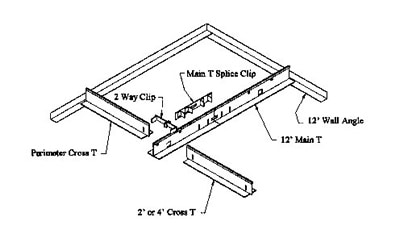

We Offer 2″ and 1-1/2″ T-Grid Systems

- The Cleanrooms International 2″ Structural T-Grid System is designed to meet the exacting standards of the cleanroom industry. Applications include food services, food processing, pharmaceutical, electronic, medical devices, chemical, and hospital industries.

- Suspension hardware provides easy adjustment for installing the ceiling dead level.

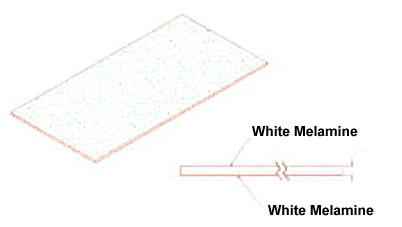

CRI Ceiling Panels

- CRI ceiling blanks are used in spaces not occupied by SAM Fan/Filter Modules, Ceiling Filter Modules, or light fixtures.

- Class 1000 – 100,000

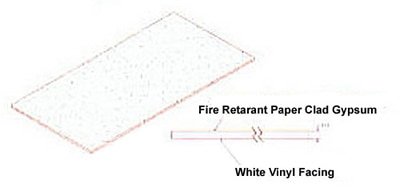

Cleanguard Ceiling Panels

- Clearguard Ceiling Panels are designed for low particle emission and maximum cleanability in cleanrooms and other environmentally controlled areas.

- Class 100</li>

Light Fixtures

Strip Light

- The CRI Teardrop light fixture is designed for use in vertical, laminar air flow cleanrooms.

- A narrow airflow design minimizes turbulence.

Lay-In Light Fixture

- Sealed flushed door frame and sealed housing.

- The housing and door are designed to fit a standard 2′ x 4′ ceiling grid opening.

- Sealed housing and door frames allow relamping without contamination of the clean areas.

Cleanroom Wall Systems That Meet Your Needs

Where critical environmental conditions must be maintained, modular cleanroom wall systems and prefabricated kit wall systems offer you a cost-effective alternative to conventional construction… without compromising quality, durability, or cleanroom efficiency.

We understand your needs, so we combined the latest, most effective cleanroom technology with a modular design that can be installed, modified, expanded, and relocated quickly and easily to meet your changing needs.

Our cleanroom wall systems provide an ultra-clean environment, with effective control of airflow, pressure, temperature, humidity, and filtration. We also give you the flexibility of a variety of core materials, exterior panels, and finishes to meet your requirements for acoustic and thermal insulation, chemical resistance, and static control.

Hardwall Modular Cleanrooms

Hardwall Modular Cleanrooms are designed with each individual customer’s needs in mind to provide ideal systems ranging from ISO Class 1 to 9. Our Cleanrooms have been installed in a broad range of industries and countries. The modularity of the wall system allows for easy expansions and modifications after the installation of the original design.

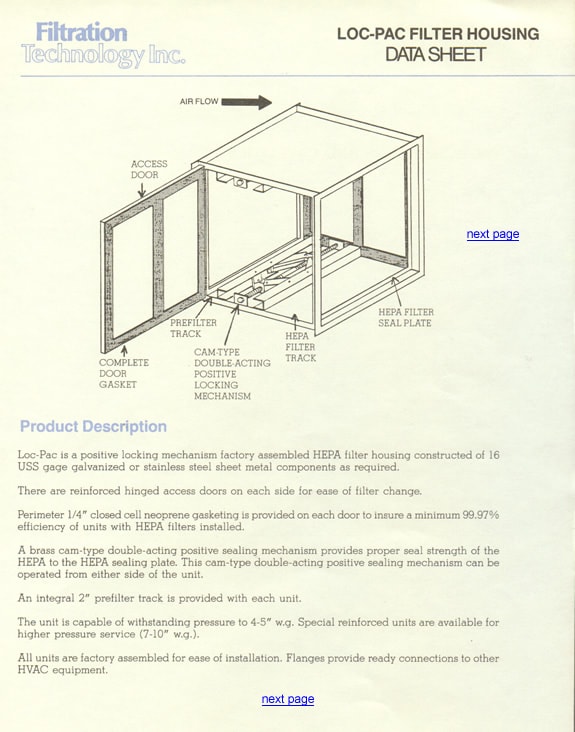

Since 1971 Filtration Technology Inc. continues to demonstrate proven leadership as FILTRATION and Contamination Control Specialists by providing the highest quality in Cleanroom Facilities and Air & Liquid Filtration to all types of commercial, industrial, and specialized manufacturing facilities.

The Modular Cleanroom

Our Modular Cleanrooms are constructed of pre-engineered and prefabricated components. These components are prefabricated at the factory, which allows for flexibility and prompt delivery, and minimizes on-site installation time. Modular Cleanroom systems have lower costs and the ability to depreciate in a shorter period of time, just like machinery or office equipment.

We have Modular Cleanroom kits available for every need:

Single-Pass Modular Cleanroom

Conditioned air to the Modular Cleanroom is provided by existing air handling equipment in the ambient space surrounding the Clean Space. Conditioned air will be HEPA filtered by Fan Powered Modules.

Recirculating Modular Cleanroom

Conditioned air to the Modular Cleanroom is provided by air handling equipment, existing or new, to the mixing plenum above the cleanroom’s ceiling grid. Conditioned air will be HEPA filtered by Fan Powered Modules, and returned to the mixing plenum to recirculate.

Ducted Supply/Free Return

Conditioned air to the Modular Cleanroom is provided by new or existing air handling via a dedicated duct network. Conditioned air will be HEPA filtered by Fan Powered Modules or Terminal HEPA filters. Return air will be exhausted to the surrounding ambient spaces and then return to the air handling equipment or mixing plenum.

Ducted supply/Ducted return

Conditioned air to the Modular Cleanroom is provided by new or existing air handling via a dedicated duct network. Conditioned air will be HEPA filtered by Fan Powered Modules or Terminal HEPA filters. Return air will be directed back to the air handling equipment or mixing plenum.

Prefabricated Kits

The Simplex AirLockT Enclosure is a modular, latch-together, cleanroom system that is a totally integrated wall and ceiling frame system. The System can be easily expanded or reconfigured to meet ever-changing demands. The most durable with sophisticated engineering.

Basic Features

- Neoprene closed-cell foam gaskets seal frame-to-frame connections.

- Vinyl inserts lock into the frame with an airtight seal; inserts cannot be knocked loose due to accidental impacts.

- Frame construction with knock-together corners allows for the replacement of individual parts.

- Universal corner posts allow for all walls to be interchangeable for future expansion.

- Ceiling frames latch into position in the same manner as the walls and can be designed to accommodate various types of filtration and lighting units.

- Lightweight aluminum frames are available in black anodized, anodized clearcoat, or epoxy powder coat white finishes.

- Free Standing

Benefits

- Modular ability to increase or shrink the size and shape of the room.

- Assembly time is very quick.

- No special tools are required for assembly.

- Finished room appearance.

- Easy to clean wall panel insert materials.

- Easy to disassemble and store when no longer required.

- Cleaning is quick and easy.

- Outstanding visibility.

- Curtain materials Approval by Fire Marshall.

Wall Material and Installation Options

Flexible PVC Curtains: Antistatic, Polysim, or Clear Standard. Colors optional.

Rigid Panels Inserts: Most industrial panels are available, plus aluminum

composites, acrylic, polycarbonate, ABS, and FRP

SIS-212 Framing Systems

One Extrusion Does It All. The Simplex SIS Modular Frame System is built around simple, strong, easy-to-assemble modules. You can quickly assemble three or four-sided modular sections and latch or screw them together. It’s that simple! Modules can be easily disassembled or expanded as your needs change.

Basic Features

- Frames knock easily together

- Free Standing

- Heavy-duty 2-1/8″ x 2-1/8″ anodized aluminum extrusion framework.

- Basic extrusion is used to build all types of structures, from simple machinery frames to

- cleanroom enclosures.

- Choice of Compression Latch or Bolt Together designs, both ensure a strong structural connection.

- Available with Simplex AirLockT ceiling modules with integrated, fully gasketed 2″ T-Grid.

- Knock-in corners for easy assembly.

- Choice of prefabricated enclosures or bulk material to build your own enclosures.

- Easy to customize to fit any application.

Benefits

- Modular ability to increase or shrink the size and shape of the room.

- Assembly time is very quick and easy.

- No special tools are required for assembly.

- Easy to disassemble and store when no longer required.

- Cleaning is quick and easy.

- Outstanding visibility curtain materials Approval by Fire Marshall

Wall Material and Installation Options

- FLEXIBLE PVC CURTAINS: Antistatic, Polysim, or Clear Standard. Colors optional.

- RIGID PANEL INSERTS: Most industrial panels are available, plus aluminum composites, acrylic, polycarbonate, ABS, and FRP.

Traditional Softwall Cleanrooms

- FRAME: Prefabricated, white-painted tubular steel. Other colors are available.

- SUPPORT: External overhead support or support legs for a self-supporting system

- CEILING SYSTEM: Painted 2″ or 3″ support beams, 1″ perimeter wall angle, and 2″ structural clear satin anodized aluminum T-Grid. All load-bearing flanges of T-Grid will be provided with a closed-cell PVC gasket.

- CURTAIN: All four sides are to be enclosed with various choices in PVC materials both standard vinyl and antistatic vinyl. Also available is Polysim; a non-outgassing, transparent, antistatic material.

- LIGHTING: Standard 2′ x 4′ cleanroom troffers or Teardrop fixtures depending on the classification of the cleanroom.>

- FILTER MODULES: Self-contained 2′ x 2′ / 2′ x 4′ / 2′ x 6′ Fan Powered HEPA/ULPA Units.

- FAN FILTER MODULES: Our SAM Fan / Filter Modules are completely self-contained with a profile as low as 12″.

Basic Features

- Bolt together frame construction

- Pre-engineered ceiling system for quick installation and design

- to accommodate various types of filtration and lighting units.

- Free Standing

Benefits

- Assembly time is quick

- No special tools are required for assembly

- Outstanding visibility

- Curtain materials Approval by Fire Marshall

Since 1971 Filtration Technology Inc. continues to demonstrate proven leadership as FILTRATION and Contamination Control Specialists by providing the highest quality in Cleanroom Facilities and Air & Liquid Filtration to all types of commercial, industrial, and specialized manufacturing facilities.